ISM Manufacturing Survey Improves, And Above Expectations

The ISM Manufacturing survey for October 2014 continues to indicate manufacturing growth expansion with an moderate increase in the rate of growth. This survey should be considered relatively strong this month, offsetting the relatively soft report last month.

The ISM Manufacturing survey index (PMI) declined from 56.6 to 59.0 (50 separates manufacturing contraction and expansion). This was above expectations which were 55.5 to 57.2 (consensus 56.0).

This index had been in a general uptrend since mid 2013 - but the three month trend relatively flat. This is the sixteenth month of expansion. The regional Fed manufacturing surveys were indicating growth in October, and now the ISM indicates manufacturing shows expansion in October also.

Relatively deep penetration of this index below 50 has normally resulted in a recession.

The noisy Backlog of Orders improved from 47.0 to 53.0 – and has now returned to expansion. Backlog growth is an indicator of improving conditions; a number below 50 indicates contraction. Backlog accuracy does not have a high correlation against actual data.

Excepts from the ISM release:

Economic activity in the manufacturing sector expanded in October for the 17th consecutive month, and the overall economy grew for the 65th consecutive month, say the nation’s supply executives in the latest Manufacturing ISM® Report On Business®.

he October PMI® registered 59 percent, an increase of 2.4 percentage points from September’s reading of 56.6 percent, indicating continued expansion in manufacturing. The New Orders Index registered 65.8 percent, an increase of 5.8 percentage points from the 60 percent reading in September, indicating growth in new orders for the 17th consecutive month. The Production Index registered 64.8 percent, 0.2 percentage point above the September reading of 64.6 percent. The Employment Index grew for the 16th consecutive month, registering 55.5 percent, an increase of 0.9 percentage point above the September reading of 54.6 percent. Inventories of raw materials registered 52.5 percent, an increase of 1 percentage point from the September reading of 51.5 percent, indicating growth in inventories for the third consecutive month. Comments from the panel generally cite positive business conditions, with growth in demand and production volumes.

Of the 18 manufacturing industries, 16 are reporting growth in October in the following order: Plastics & Rubber Products; Textile Mills; Fabricated Metal Products; Miscellaneous Manufacturing; Primary Metals; Electrical Equipment, Appliances & Components; Nonmetallic Mineral Products; Food, Beverage & Tobacco Products; Chemical Products; Apparel, Leather & Allied Products; Printing & Related Support Activities; Transportation Equipment; Furniture & Related Products; Paper Products; Machinery; and Computer & Electronic Products. The only industry reporting contraction in October is Petroleum & Coal Products.

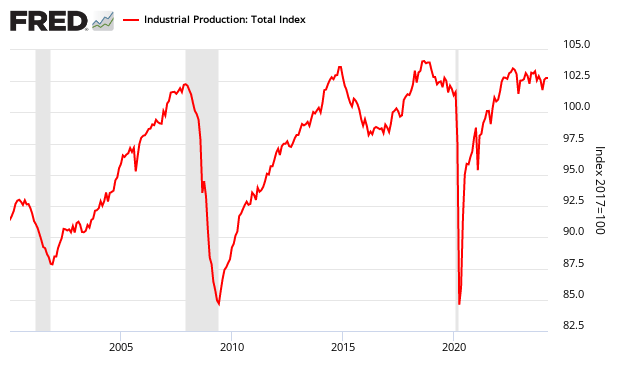

It is interesting to note that ISM Manufacturing represents less than 10% of USA employment, and approximately 20% of the business economy. Historically, it could be argued that the production portion of ISM Manufacturing leads the Fed’s Industrial Production index – however the correlation is not strong when looking at trends.

New orders have direct economic consequences. Expanding new orders is a relatively reliable sign a recession is NOT imminent. However, New Orders contraction have given false recession warnings twice since 2000.

However, holding this and other survey’s Econintersect follows accountable for their predictions, the following graph compares the hard data from Industrial Products manufacturing subindex (blue bar) and US Census manufacturing shipments (red bar) to the ISM Manufacturing Survey (purple bar).

Comparing Surveys to Hard Data

![]()

Caveats on the use of ISM Manufacturing Index:

This is a survey, a quantification of opinion – not facts and data. However, as pointed out above, certain elements of this survey have good to excellent correlation to the economy. Surveys lead hard data by weeks to months, and can provide early insight into changing conditions.

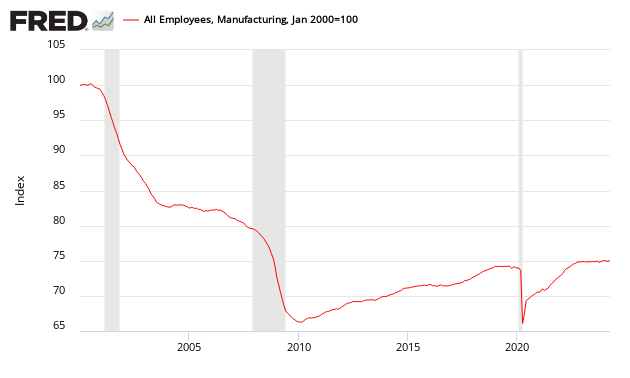

Many use ISM manufacturing for guidance in estimating manufacturing employment growth. Econintersect has run correlation coefficients for the ISM manufacturing employment and the BLS manufacturing employment data series above going back to 1988, using quarterly data. The coincident correlations are actually negative, but poor (r = -0.2 to -0.4 for various time periods examined). See here for definitions.

Before 2000 the ISM employment data had a weak positive correlation to the BLS data 4 to 7 quarters later (r values above 0.6). Since 2000 the correlations for ISM manufacturing employment as a leading indicator for the BLS manufacturing employment have been between 0 and 0.3 for r (correlation coefficient). These values define correlations as none to poor.

In other words, ISM employment index is not useful in understanding manufacturing jobs growth.

The graph below shows BLS manufacturing employment month-over-month gains against the ISM Manufacturing employment index.

Indexed to Jan 2000 – Comparison of the ISM Manufacturing Employment Subindex (blue line) to BLS Manufacturing Employment (red line) – all data seasonally adjusted

The ISM employment index appears useful in predicting turning points which can lead the BLS data up to one year.

Disclosure: None.